You probably know the difference between a blanco, reposado and añejo tequila is the amount of time it was barrel-aged. But what distinguishes one tequila from another? If all tequila is crafted from blue Weber agave and has been cooked, fermented and distilled, what makes the difference between a humdrum bottle and a truly standout product?

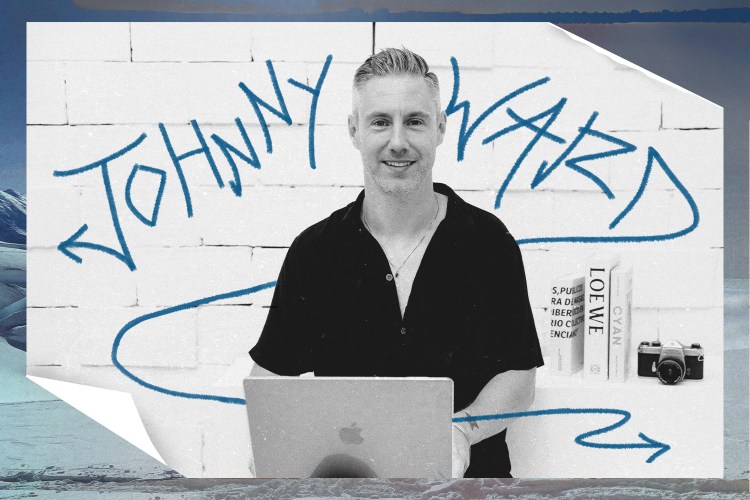

The team at Cazcanes Tequila is clearly doing something right. They’ve entered their products in the San Francisco World Spirits Competition three times and come away with a Double Gold each time, including a Best In Show award for an unaged white spirit. We were recently invited by Cazcanes CEO Jon-Paul Fortunati to Jalisco, Mexico to experience their process start-to-finish.

In the hills of Hostotipaquillo, we sipped spring water freshly pumped from their proprietary natural source. We watched a jimador in a field in Amatitan harvest an agave plant, expertly stripping the leaves off with a metal coa. We tasted a bit of agave, freshly cooked from the autoclave (two bits, actually, from different parts of the plant: the fibrous pencas and the smoother corazon, with a texture and sweetness evocative of a grainy date fruit). Standing several feet away from the cooper, we could feel the heat from his blowtorch as he gave a fresh char to the inside of a bourbon barrel to prepare it for aging tequila.

Here are some takeaways about decision points in tequila production, as practiced by Cazcanes and other premium makers, that can mean the difference between something ordinary and something special. And note, there are certainly more than eight factors — location, extraction methods, types of stills, etc. all play a role in what ends up in your glass.

Sugar Level at Harvest Time

Rising climate temperatures mean agaves are aging faster. Although there’s a lot of marketing hype about eight- to 10-year-old agave plants, after a certain point, what really matters is the agave’s sugar level, measured on the Brix scale just like wine grapes. Brix refers to the amount of dissolved solids in a liquid, and a reading can be taken in the field by extracting a few drops of juice from the plant onto a gadget called a refractometer. Non-premium tequila might be from agave harvested before the sugars have fully developed. (Side note: A refractometer could be the perfect present to bring to your office’s annual Secret Santa gift exchange. You’re welcome.)

Bald vs Stubbly Piñas

Two other plants can help you understand agave: an artichoke and a pineapple. Like an artichoke, agave has leaves (pencas) atop a heart, which turns soft when cooked. The body is called a piña for its resemblance to a pineapple. At harvest time, the jimador removes the long, spiky leaves with his tool, the coa, right there in the field before loading the piñas onto the truck. The cogollo is a bitter part near the top that can be removed when the piña is chopped open. A decision point is how obsessive to be about the vegetal part where the pencas are connected. Cazcanes prefers to allow about 2-3cm of the pencas to remain, to add nuance and herbal notes to the finished product.

Loco Tequila goes in the other direction. They use a technique called the double jima, whereby a second shave is done at the distillery to remove every bit of extraneous matter from the white flesh of the piña before cooking. Their goal is a refined, rich distillation.

Water Source

If you see a tanker truck with the Cazcanes logo on Federal Highway 15 in Jalisco, it might be fun to daydream that it’s full of tequila, heading to the best tailgate party ever. But it actually contains pristine volcanic natural spring water that’s freshly pumped from the Navichi Springs, and the truck is en route to the distillery. Because water is one of just three ingredients in premium tequila, along with agave and fermentation yeast, quality matters. Cazcanes also uses it to rinse the fibers of the cooked agave as it gets shredded in the roller mills before fermentation.

Premium brands run mineral content analysis on their water source. The makers of G4 Tequila use a 50/50 blend of collected rainwater and spring water from uphill of their distillery and deep well water for their reposado.

Cooking Method and Pressure

Cooking agave converts the starches into fermentable sugars. Centuries ago, here’s how you’d do it: Dig a pit in the ground, line it with rocks, add charcoal and wood, put the agave on top, then cover with leaves and soil to slow roast for a few days. (A similar method is still used for mezcal.) In a nod to that tradition, Siembra Spirits uses an earthen pit to create their Siembra Valles Ancestral tequila. But for scalable production, tequila makers use steam heat from either a brick (or stone) oven or a huge steel chamber called an autoclave.

The brick oven isn’t like a kitchen oven where you cook your dinner; it’s at least the size of a walk-in closet, and the piñas are stacked up inside. The highly sippable DE-NADA is made from agave cooked in brick ovens at the Vivanco Distillery in Arandas, Mexico and has an earthy flavor with notes of cinnamon.

On the other hand, think of an autoclave like a pressure cooker. A high-pressure autoclave, used by plenty of mass-market tequilas, has the advantage of speed but can result in less complex flavor. Premium tequila makers will use a low-pressure autoclave to allow for full caramelization and development of the agave. Cazcanes uses a 24-hour process, including eight hours of low-pressure steam, followed by residual heat and then an eight-hour cool-down. “We find this method to be ideal for bringing out a vibrant, agave-forward character while allowing deeper, nuanced flavors to emerge,” Fortunati says.

Fermentation Yeast

For top-notch tequila makers, there is yeast and then there is yeast. Penta Tequila, founded by five guys with a background in California winemaking, was the first to use Champagne yeast in agave fermentation. Co-founder Steve Reynolds attributes Penta’s sweet, almost floral notes to this decision. “We tried it side by side with another tank that had used traditional Mexican industrial tequila yeast,” he says. “We knew then and even when it fermented that the aromas were better.”

The Cazcanes team had an interesting journey. “Originally, we used wild yeast for fermentation, meaning we relied entirely on open-air fermentation, allowing natural yeast from the air and environment to initiate the process,” Fortunati says. “This method was integral to our original production, contributing unique characteristics that became a signature of our flavor profile.” When they moved into their current facility, they sent samples to a lab for analysis. From that work came the creation of the proprietary yeast strain they use, which has allowed for consistency of flavor.

Post-Distillation Oxygenation

The art of knowing when to make the “cuts” of the heads, hearts and tails is part of the distiller’s craft for any spirit, not unique to tequila. But there’s a subsequent step some tequila makers do to help cut out the sharp bite on the palate. Pumping some air into the vat helps smooth out the taste and makes it more approachable. The trick is not to overdo it. Cazcanes’s Master Distiller “Don Chico” Jimenez constantly monitors the batch when oxygenating.

This Luxury Tequila Is So Exclusive You May Never Get to Try It

Volcan X.A was built exclusively for clubs and high-end restaurants. We flew out to Las Vegas to get a taste.Next-Level Blending

Visualize a cellar of oak barrels containing tequila, rows and rows of it arranged according to how long it’s been aging. You could take a formulaic approach to creating a batch, treating the barrels as if they’ve been waiting in line: Grab the first dozen barrels that have aged six months, and you’ve got your reposado. Leave some to age for more than a year, and there’s your añejo. But crafting tequila is art, not algebra.

Volcan X.A is a luxury product that was conceived by the Moët Hennessy team to blend concepts more traditional to winemaking than tequila. They’ve been mixing things up by, well, mixing things up. Each batch contains a blend of reposado, añejo and extra-añejo tequila. When first launched, it was available only at a select number of clubs and restaurants to build a fan base among their target high-end clientele.

The premise Cazcanes operates from is each barrel has unique characteristics and flavor profiles that influence the aging process. That’s especially true because they begin with used bourbon barrels, from which they scrape out the previous char and re-char with a blowtorch at different levels (either at a light, medium or heavy char). “We may open and taste up to 200 barrels to create a blend that ultimately includes only 40 to 45 barrels,” Fortunati says. Lightly-aged tequila has a vibrant, fresh presence. There’s an area of their barrel room containing well-aged tequila about which they maintain barrel-specific tasting notes. They can then use that area as a sort of pantry, knowing which barrel to requisition when seeking particular flavors (e.g. caramel, butterscotch, oak) to balance a batch.

Additive-Free

A last step to mention isn’t something premium tequila makers do but rather something they generally don’t do. Additives like glycerin for mouthfeel or vanilla for sweetness have been used for decades. How to define the term “additive-free” for certification purposes and which official or non-official organization should do so is a topic of current dispute, but for some tequila drinkers, it’s an important distinction.

Our thoughts? Visit a few distilleries. Try a lot of tequilas. You’ll begin to figure out what you like, and as you work backwards, you may notice you prefer a particular method of tequila production.

Every Thursday, our resident experts see to it that you’re up to date on the latest from the world of drinks. Trend reports, bottle reviews, cocktail recipes and more. Sign up for THE SPILL now.