Nota bene: All products in this article are independently selected and vetted by InsideHook editors. If you buy something, we may earn an affiliate commission.

This is part of InsideHook’s list of The 100 Best American-Made Products, a celebration of the gear, clothes and goods that make up our lives, and are the life’s work of our fellow Americans.

“If you think about American economic history, there was a time not that long ago that the textile manufacturing industry was a cornerstone of our economic activity as a country,” says Ross Widmoyer. “There were hundreds of these mills.”

Widmoyer is talking specifically about vertically integrated woolen mills, of which there are now only two left in the entire U.S. He is the president and CEO of one of them, Faribault Mill, which is named after the city in Minnesota where it’s resided since 1865, and which produces one of my personal favorite American-made products: the Cabin Wool Throw Blanket.

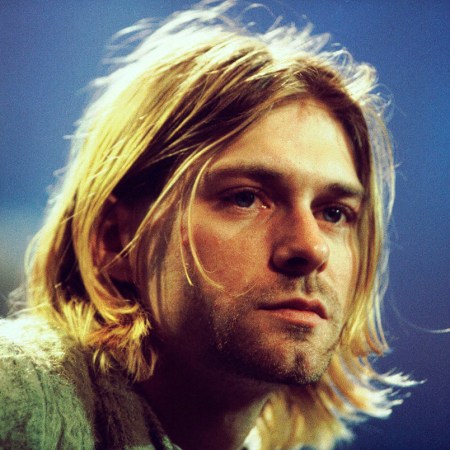

A Faribault staple for decades, the Cabin Wool Throw may look, in its product page online, like any other blanket, with its traditional striped pattern and color options that only get as eccentric as honey, orange and olive, but once you run your hands along the surprisingly soft wool and drape it over yourself, like Harrison Ford in 1923, the difference in quality becomes immediately apparent. But the first impression isn’t the point here; 30 years later, when you’re sitting next to a roaring bonfire under the stars and under the same Faribault blanket, that’s when you’ll truly appreciate what this historic mill has to offer.

“There are over 20 unique steps that go into the process of making one of our blankets,” Widmoyer explains, and that’s all under Faribault’s own roof (which, by the way, has been the same building since 1892, with various additions over the years). They start by bringing in raw wool, which goes through a picker house, then into carding, spinning and coning machines to make yarn, which is then put onto looms (either a dobby or jacquard) for weaving, followed by a wet-dry finishing process and the final cutting, sewing and shipping.

It’s a time-tested style of manufacturing, which relies on a dedicated workforce in Faribault, some of them part of multiple generations who have worked at the factory. Even some of the looms have even been in operation for over 50 years. But Widmoyer — who joined Faribault in 2020 along with chairman Paul Grangaard after both helped revive another heritage company, Allen Edmonds — isn’t relying solely on the past.

“We just made a multi-million-dollar investment to upgrade our facility with new equipment to take us into the next century,” he says, “to be able to scale to support the growth that we’ve been experiencing.”

That machinery includes a seven-figure custom industrial dryer from Italy that was designed specifically for Faribault’s space, which was incorporated about a year and a half ago, as well as investing in their unique washing process “that helps create softness,” a signature for the company that you won’t find with all, or even most, wool blankets.

“I would put our product up against any product made anywhere in the world,” he adds, “because, as I tell people all the time, if we weren’t one of the best makers and manufacturers of blankets in the world, we would have been gone a long time ago.”

We've put in the work researching, reviewing and rounding up all the shirts, jackets, shoes and accessories you'll need this season, whether it's for yourself or for gifting purposes. Sign up here for weekly style inspo direct to your inbox.