Optimism about 3-D printing’s impact on the medical field has been validated by the production of the first heart-on-a-chip.

Built by Harvard University researchers, who published their results in Nature Materials, the chip is a synthetic heart replacement that has been integrated with sensors, which collect data about cardiac tissue development and maturation in a noninvasive and readable way. This last detail is crucial, because according to Dr. Johan Ulrik Lind, “there has been a lack of easy, noninvasive ways to measure the tissue functional performance.” Lind, a postdoctoral fellow at the Harvard John A. Paulson School of Engineering and Applied Sciences (or SEAS), goes on to say that “these integrated sensors allow researchers to continuously collect data while tissues mature … [and] similarly, they will enable studies of gradual effects of chronic exposure to toxins.”

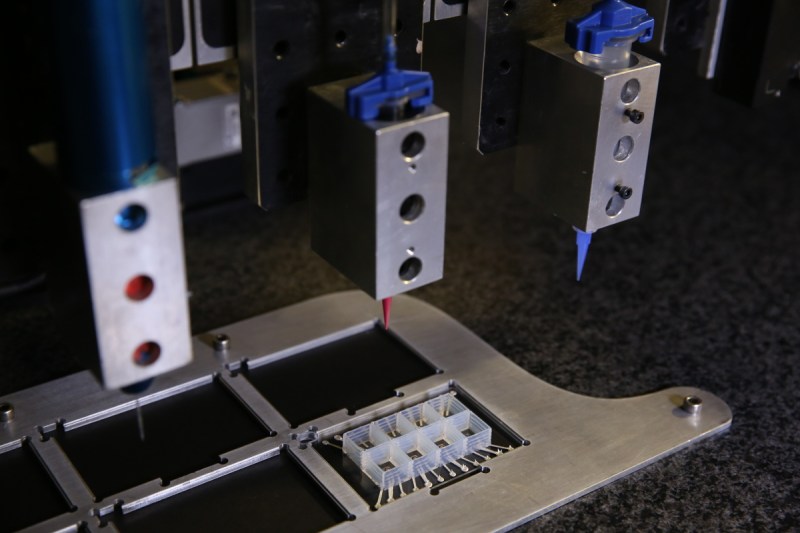

Researchers also hope that organs-on-a-chip will replace animal testing as the primary method of observing synthetic tissue implants, and this Harvard research is a beacon of light on that front. Their heart chip was made with a fully automated, digital production process that is cheaper and much less labor-intensive than prior manufacturing methods, and could be an important step towards creating organs on demand for patients who can’t wait for donors.

Below is a short video from SEAS about the chip and its manufacturing process.

The Charge will help you move better, think clearer and stay in the game longer. Subscribe to our wellness newsletter today.