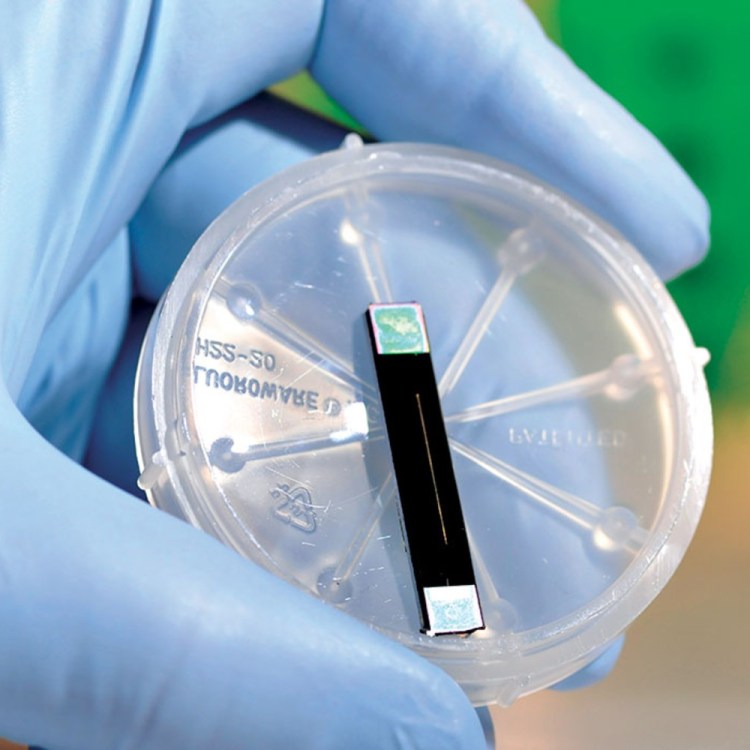

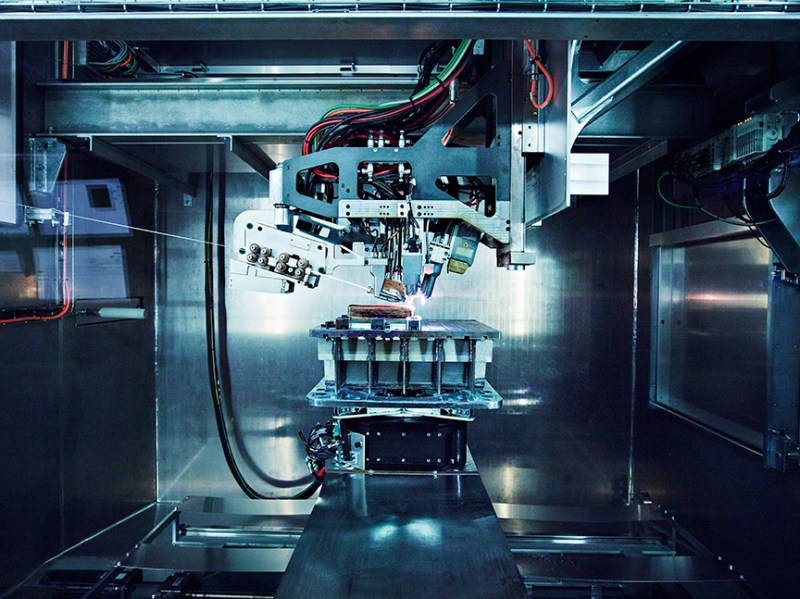

Boeing has tapped Norsk Titanium AS to produce the first 3D-printed parts approved by the FAA for its 787 Dreamliner, dramatically cutting production costs.

The contract, announced Monday, is a sign of industrial acceptance in the durability of additive manufactured parts. It will also be a boon to the airline’s 787 profit margin.

Boeing is trying the ultimate pilot program: using 3D printing to manufacture parts of their airplanes.

According to Reuters, 3D printing titanium parts would shave between two and three million dollars off the cost of each plane. Seven times the price of aluminum, the stronger and lighter titanium alloy makes up $17 million of the total $265 million required to build the Dreamliner.

Cutting costs on the 787 has been a priority for Boeing because its fuselage and wing design needs more carbon-fiber than other models. The airliner worked with Norsk for over a year to developed four 3D-printed parts and get them approved by the FAA.

Production will begin in Norway, but will expand to a facility with nine printers in Plattsburgh, New York by the end of the year.

—RealClearLife

This article appeared in an InsideHook newsletter. Sign up for free to get more on travel, wellness, style, drinking, and culture.