With generative design, it’s likely that the next big invention will come from a computer instead of a human. The current process for most design, whatever the product may be, is largely the same. Explicit design starts with an imaginary concept that’s then sketched out, modeled, and tested. For the most part, the finished product almost always resembles the initial idea, even if only slightly. However, generative design, which employs computing power in place of brainpower, completely rejects this idea.

With generative design, manufacturers start with a set of objectives that the product is intended to solve. Depending on the product, these specific goals may vary, but they can apply to anything from hip transplants to bike parts. The latter, for example, may need to be mass produced at a certain price point, have a maximum weight of seven grams, and be able to support a rider’s weight up to 350 pounds. Once these objectives have been solidified, an algorithm creates a range of potential solutions to meet them. Somewhere among the options generated by the computer is a concept that a designer is likely to have never imagined but made possible through a massive amount of computing power.

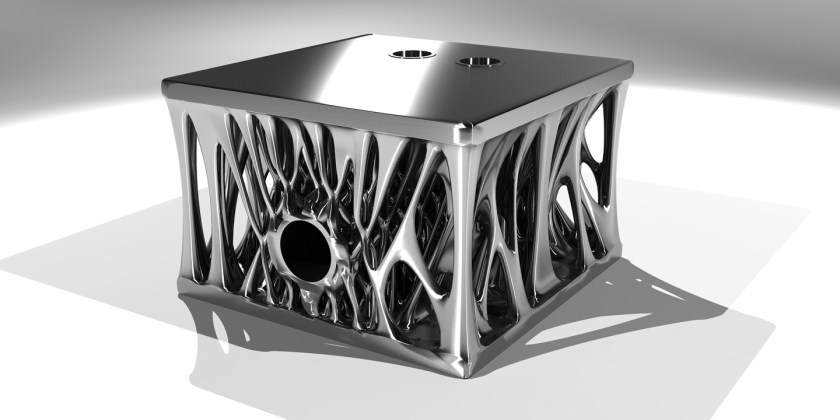

In conjunction with 3-D printing, generative design makes forms with precise amounts of material only where needed, allowing for the most potential with the least amount of waste. Software can even be used to optimize a design based on material limitations, too. Yet that’s only the start. Once prototypes are created, they can be laden with sensors that generate data during testing. If the first design isn’t a viable option, testing data is fed back into the generative design algorithm to create an improved set of options. The object basically helps design itself.

Generative design, which combines 3-D printing and machine learning, is still a new field, but it holds promise. Its benefits of reducing development time, material consumption, and costs could be enough to have investors and designers yearning to get their hands on it.

Wired recently explored the concept with Autodesk, which has their own generative design software called Dreamcatcher. The software is being used by Airbus and Under Armour to influence its products. To learn more about this, click here. Or, watch the video below.

—RealClearLife Staff

This article appeared in an InsideHook newsletter. Sign up for free to get more on travel, wellness, style, drinking, and culture.